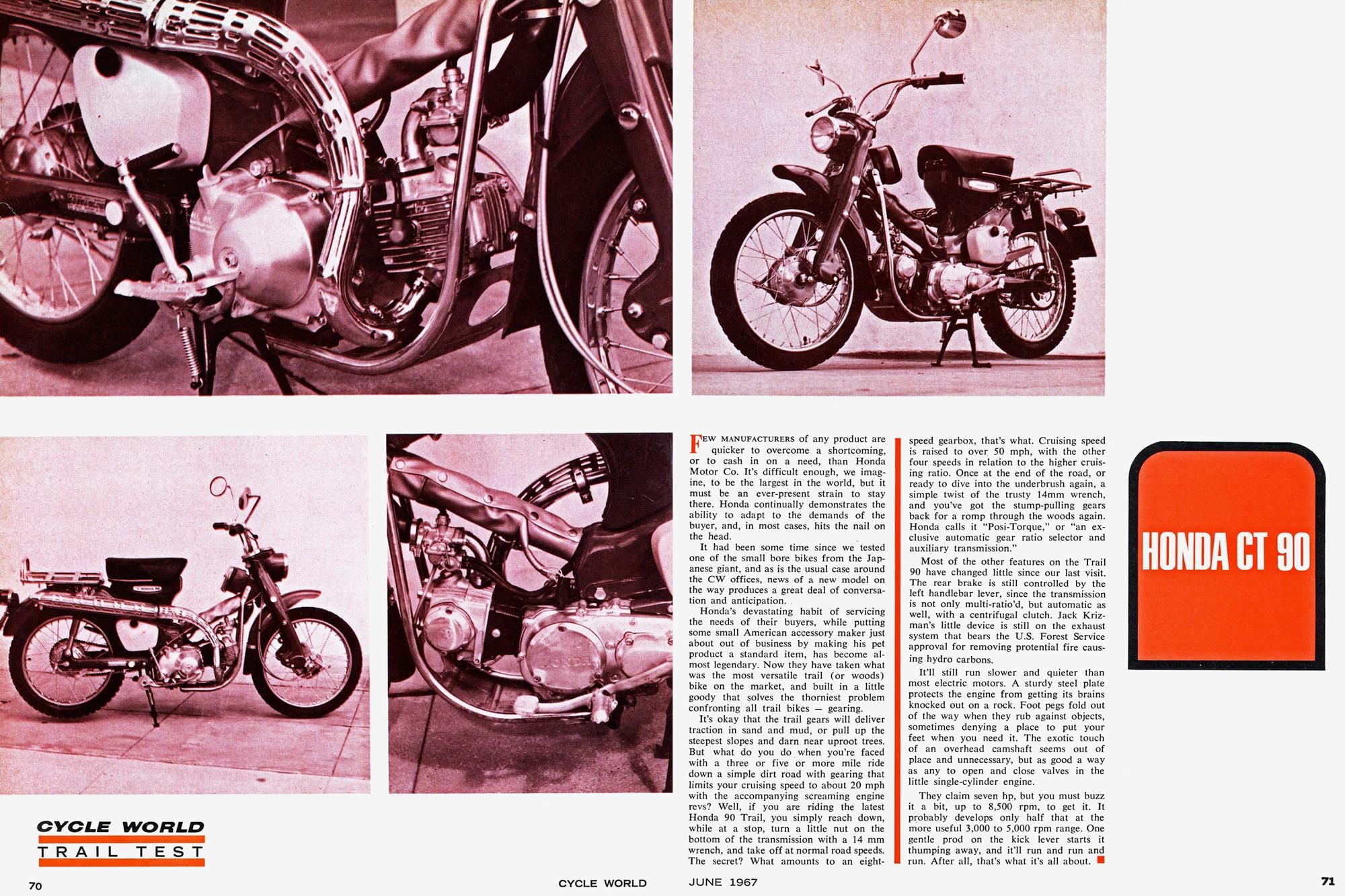

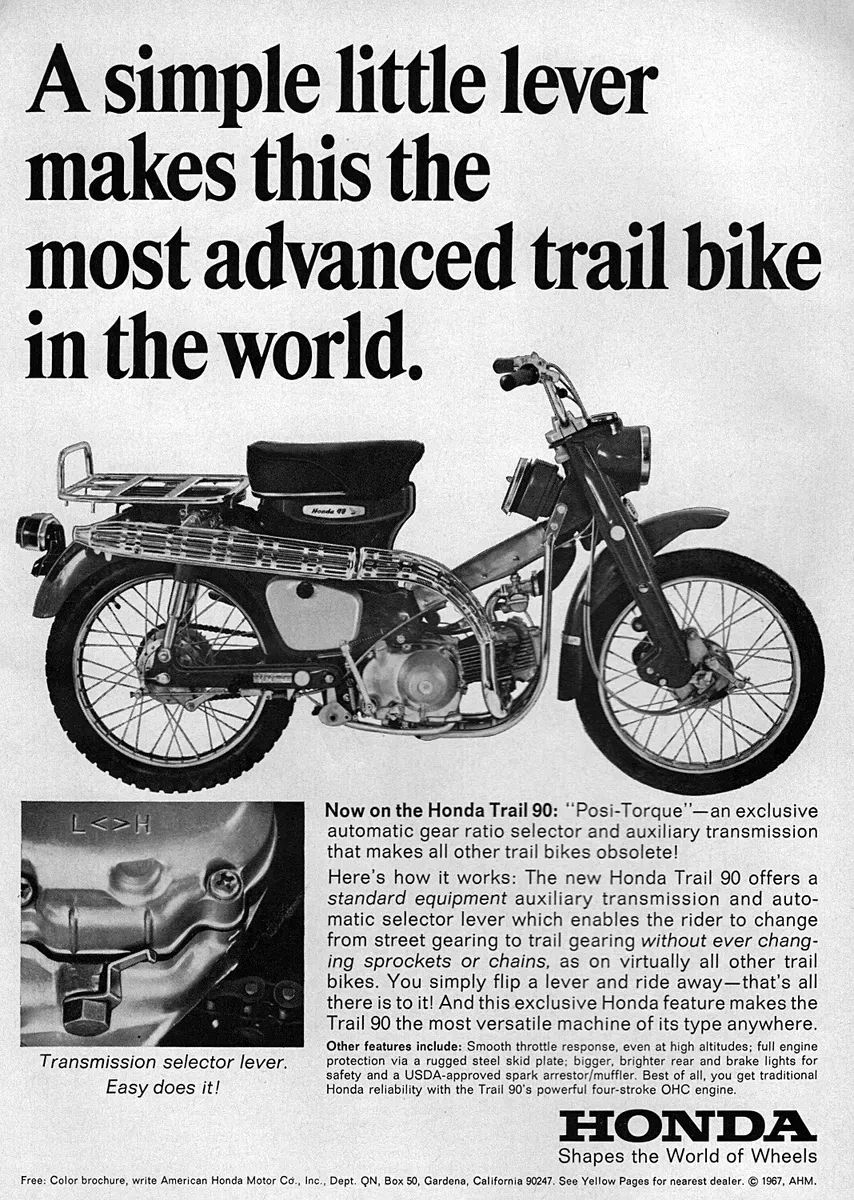

Honda invented the posi-torque system in 1967 and used it on the CT90 range of the same year. This ingenious device had the effect of providing the bike with 4 additional hillclimbing gears in addition to the standard 4 ratios for road-riding

left: Cycle World's 1967 review of the posi-torque model / right: advert announcing the new model

Earlier solutions

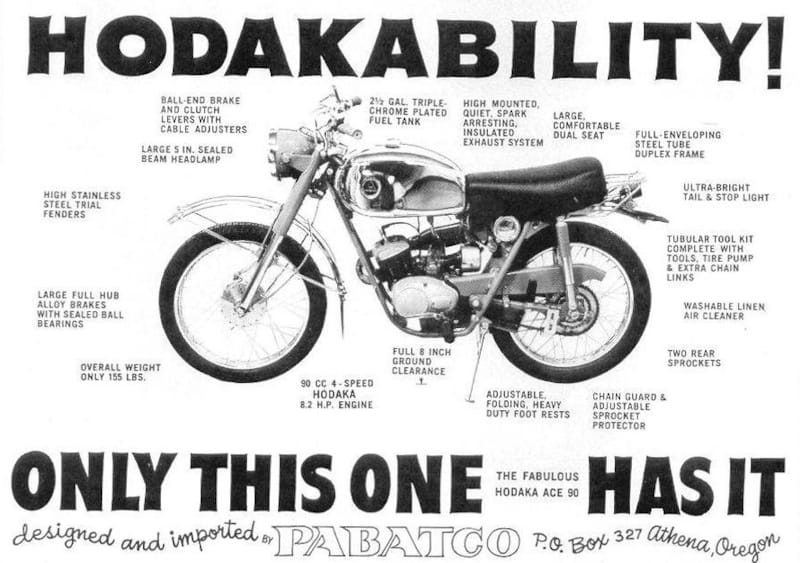

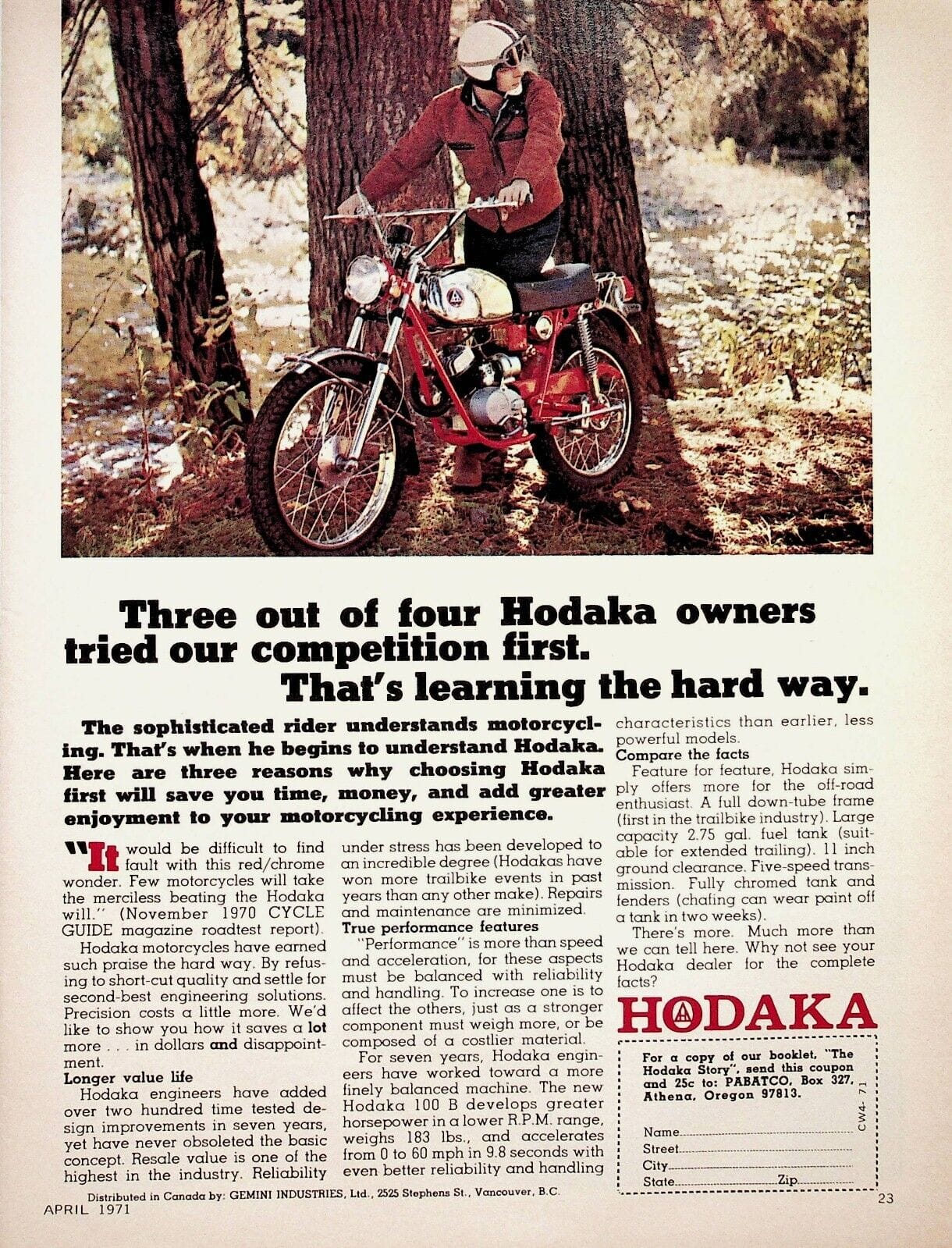

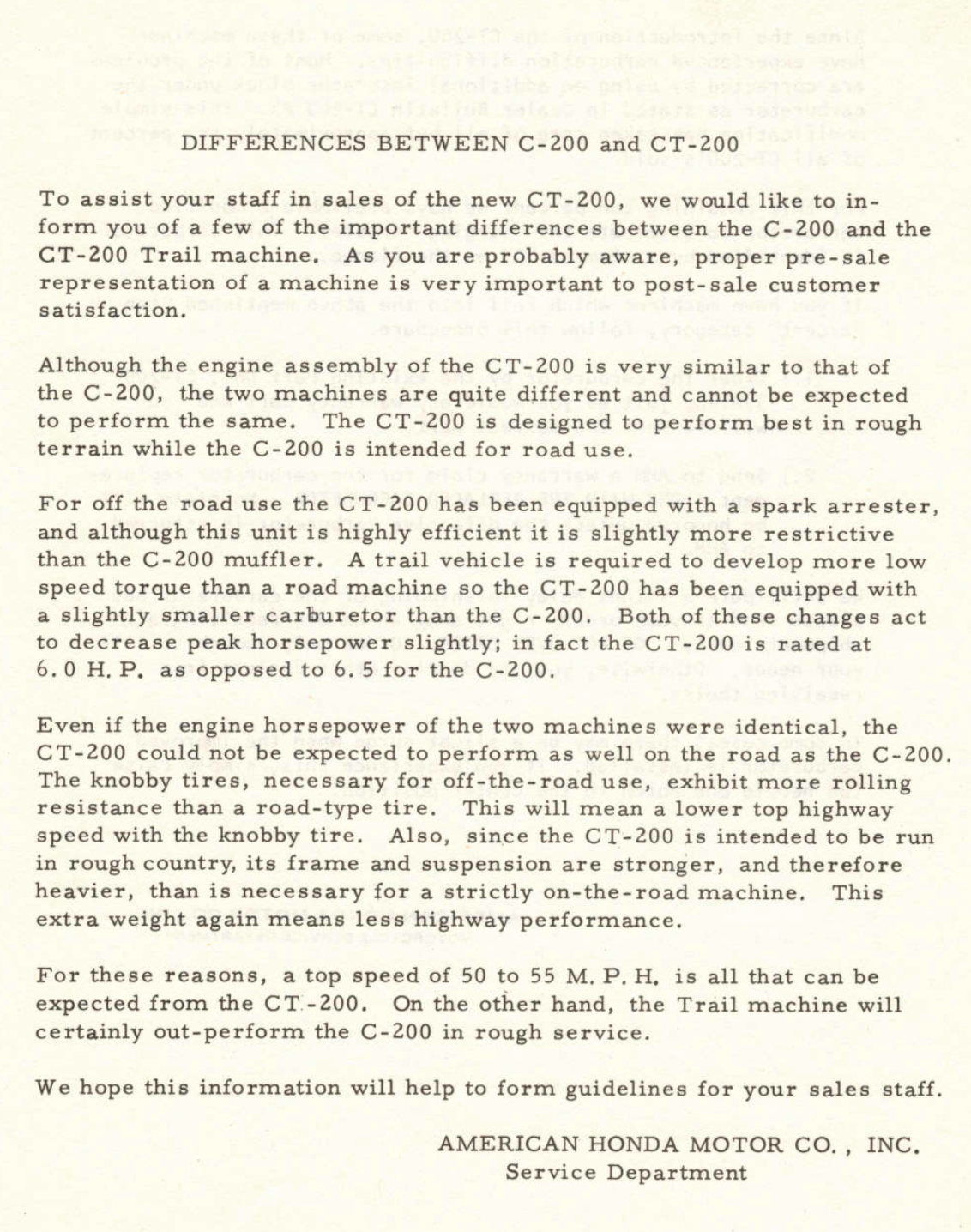

The posi-torque system replaced the unwieldy dual rear sprocket arrangement used on the earlier bikes. Many other brands - including Kawasaki, Bridgestone and Hodaka - offered dual sprockets on their trail bikes of the era, but they were all a bit of a faff to use.

The Yamaha 100 Trailmaster (1967) and the legendary Hodaka Ace 90 (1964) both had dual rear sprockets

The Honda version required the rider to stop, relocate the large sprocket from its storage mounting and then clip in an additional section onto the chain so that the larger rear sprocket could be used. Although this procedure did not require removal of the wheel it was still a 10-15 minute job, and the posi-torque - which required the use of a simple lever - was therefore a huge improvement.

The original Trial 90 with dual rear sprocket

how it works

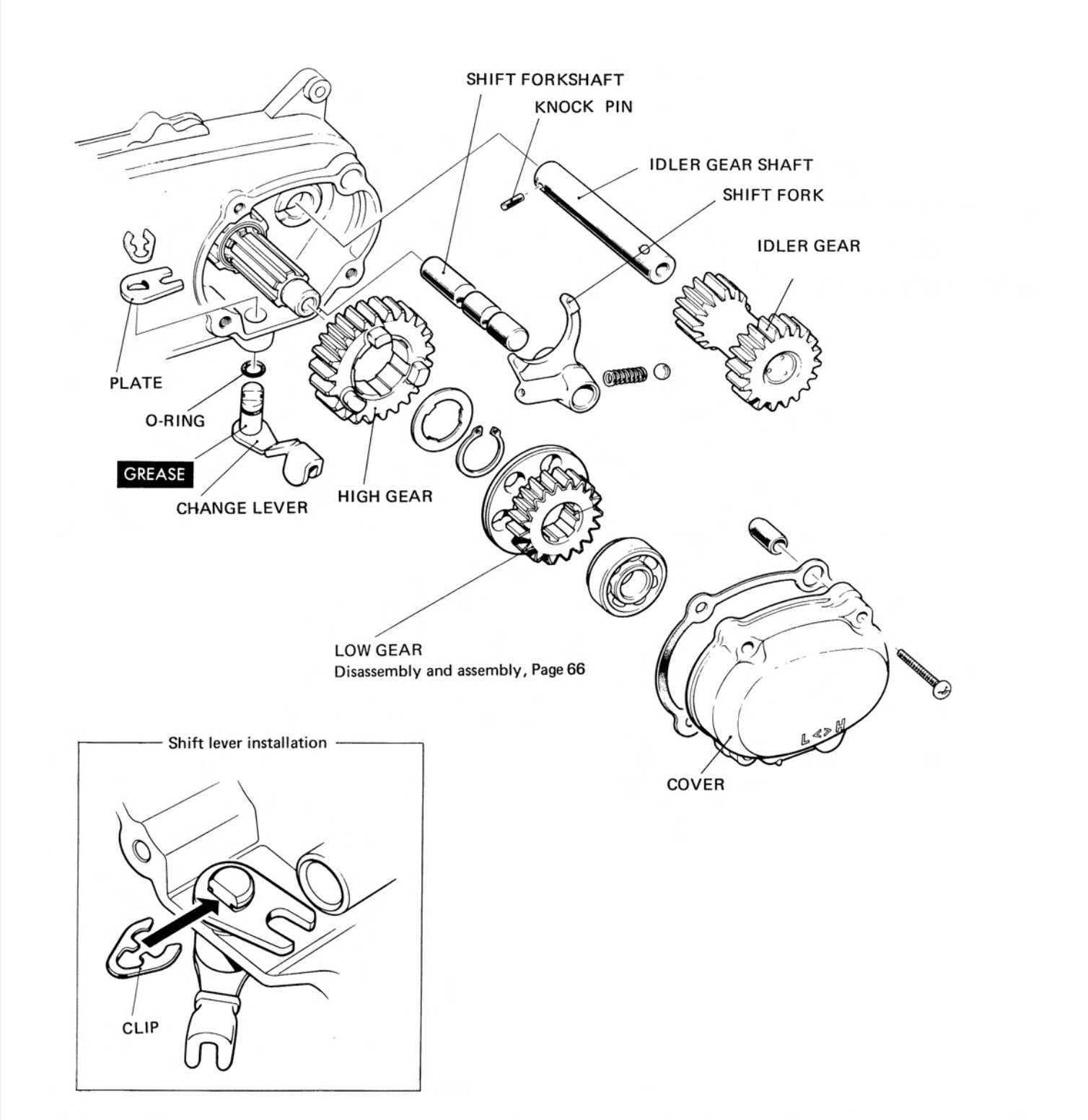

The mechanism uses very few parts

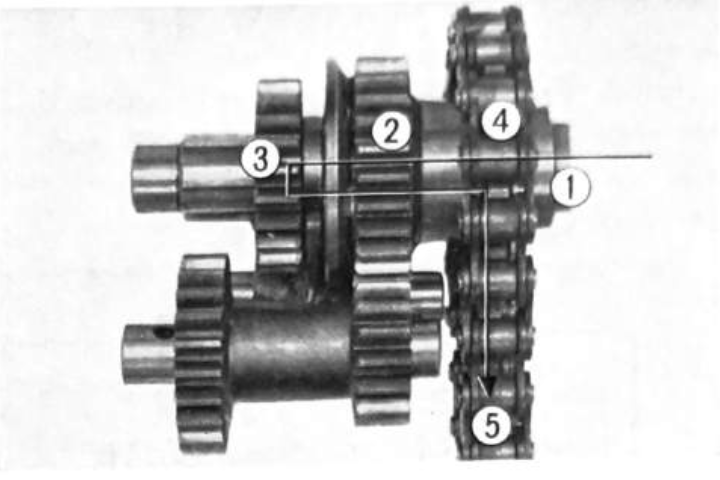

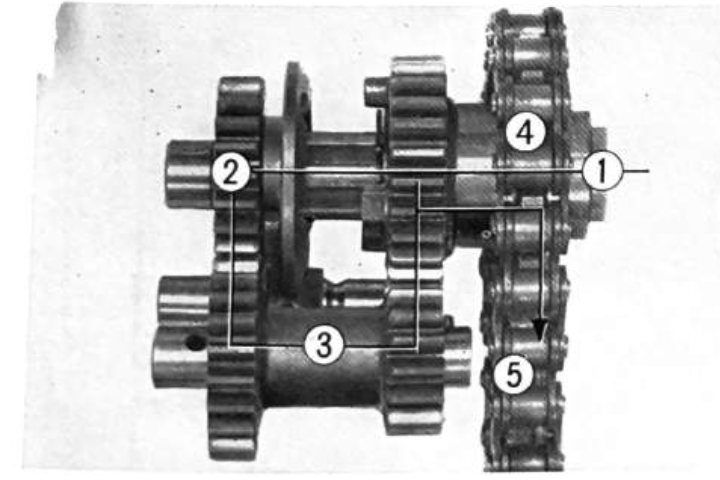

sub-transmission parts

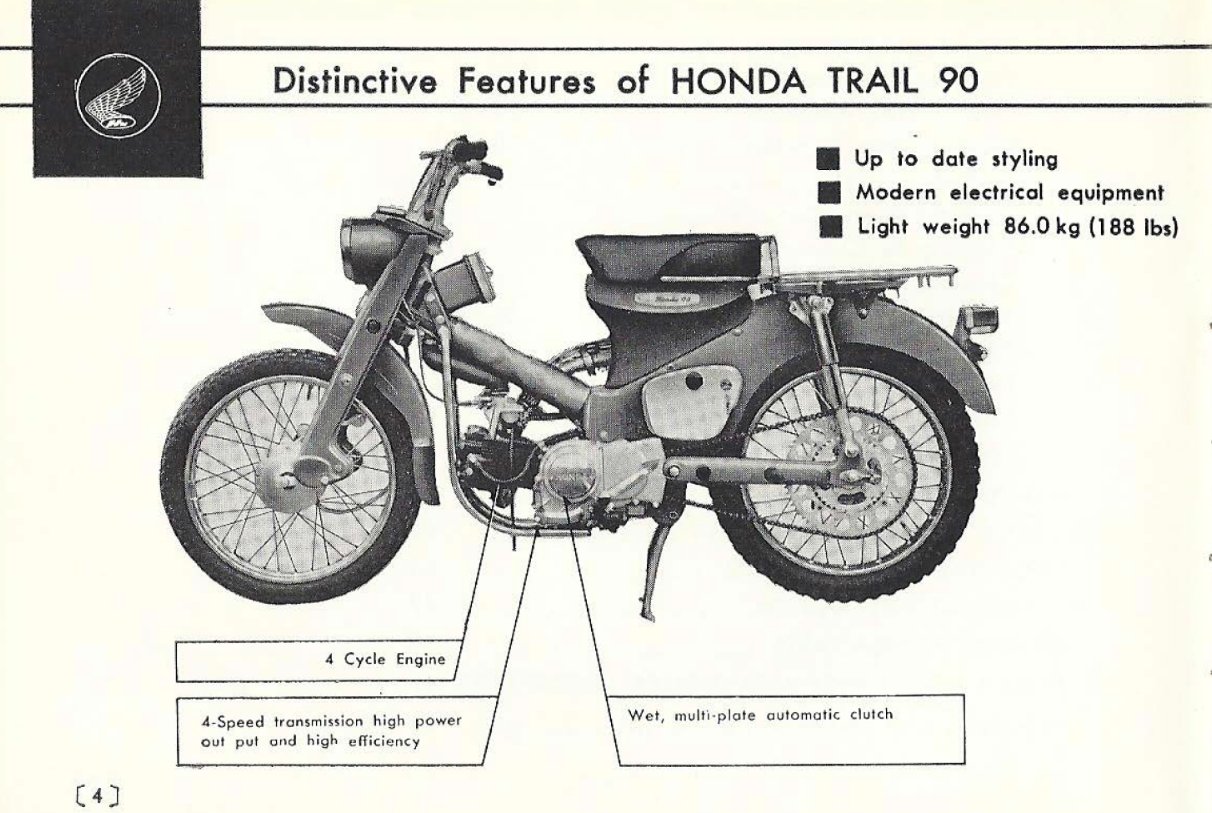

The rear wheel sprocket is mounted on a longer than standard counter (output) shaft which extends through the left hand case where the sub transmission gears are installed.

The high gear is splined to the sprocket that drives the chain and this combined unit is free to rotate on the counter shaft. The low gear (shown on the left, below) is splined to the counter shaft and the lever underneath the mechanism moves it backwards and and forwards.

In the high speed range, the selector lever is pushed to the right and the gear fork moves the splined low gear (#3, below) to lock with the sprocket/high gear unit (#1). The power is transmitted from the posi-torque low gear directly to the sprocket/high gear unit to drive the sprocket at the same speed as the counter shaft.

In the low speed range, the lever is pushed to the left and the gear fork moves the splined low gear (#2 below) to mesh with the idler gear (#3) and then to drive sprocket/high gear unit (#4) where the speed reduction takes place.

Perhaps the most ingenious aspect of the invention is that it could be added to the original 6v engine without major reconstruction: the CT90 posi-torque engine is essentially the previous version with a different left hand case and a handful of extra parts. Honda patented the invention in 1967.

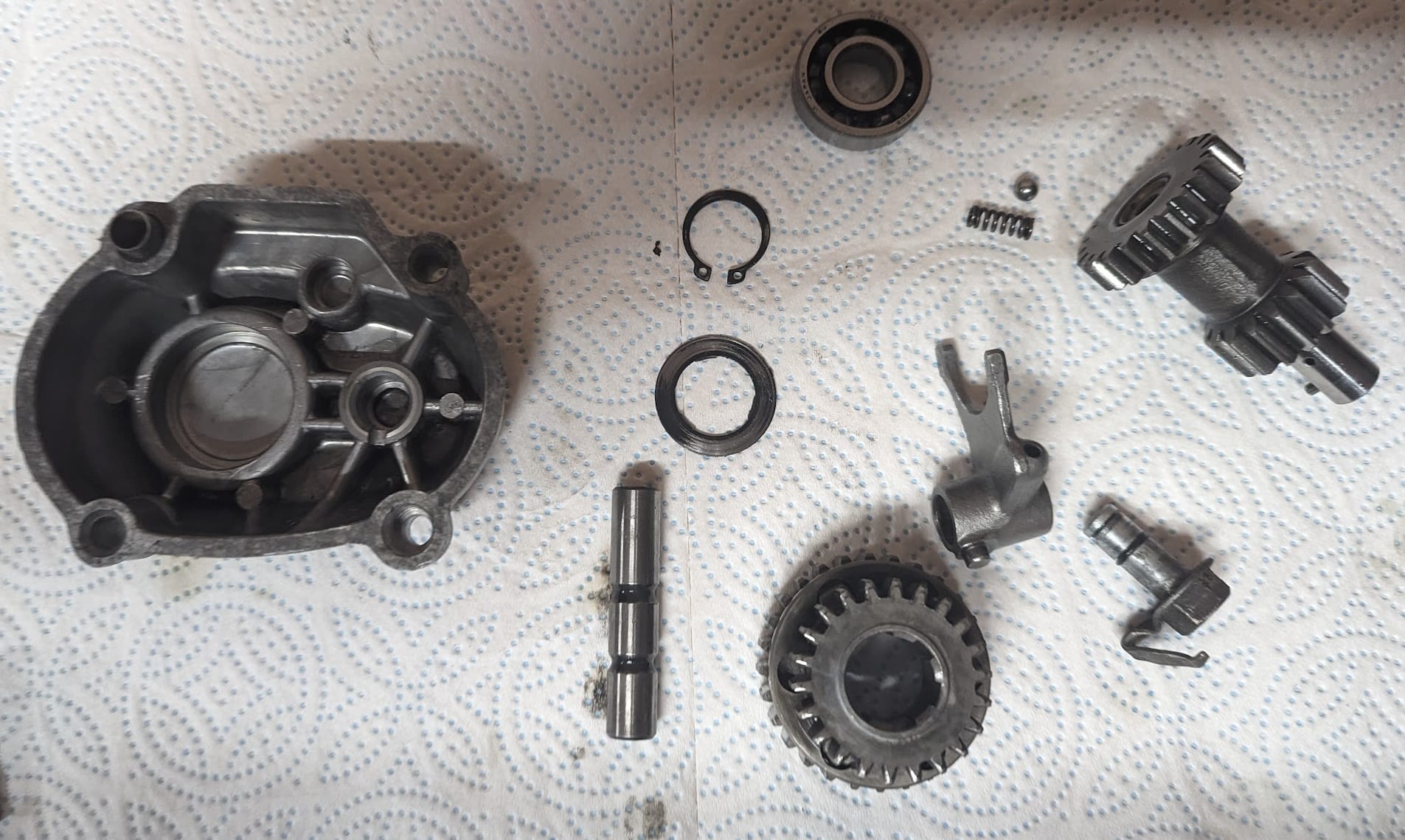

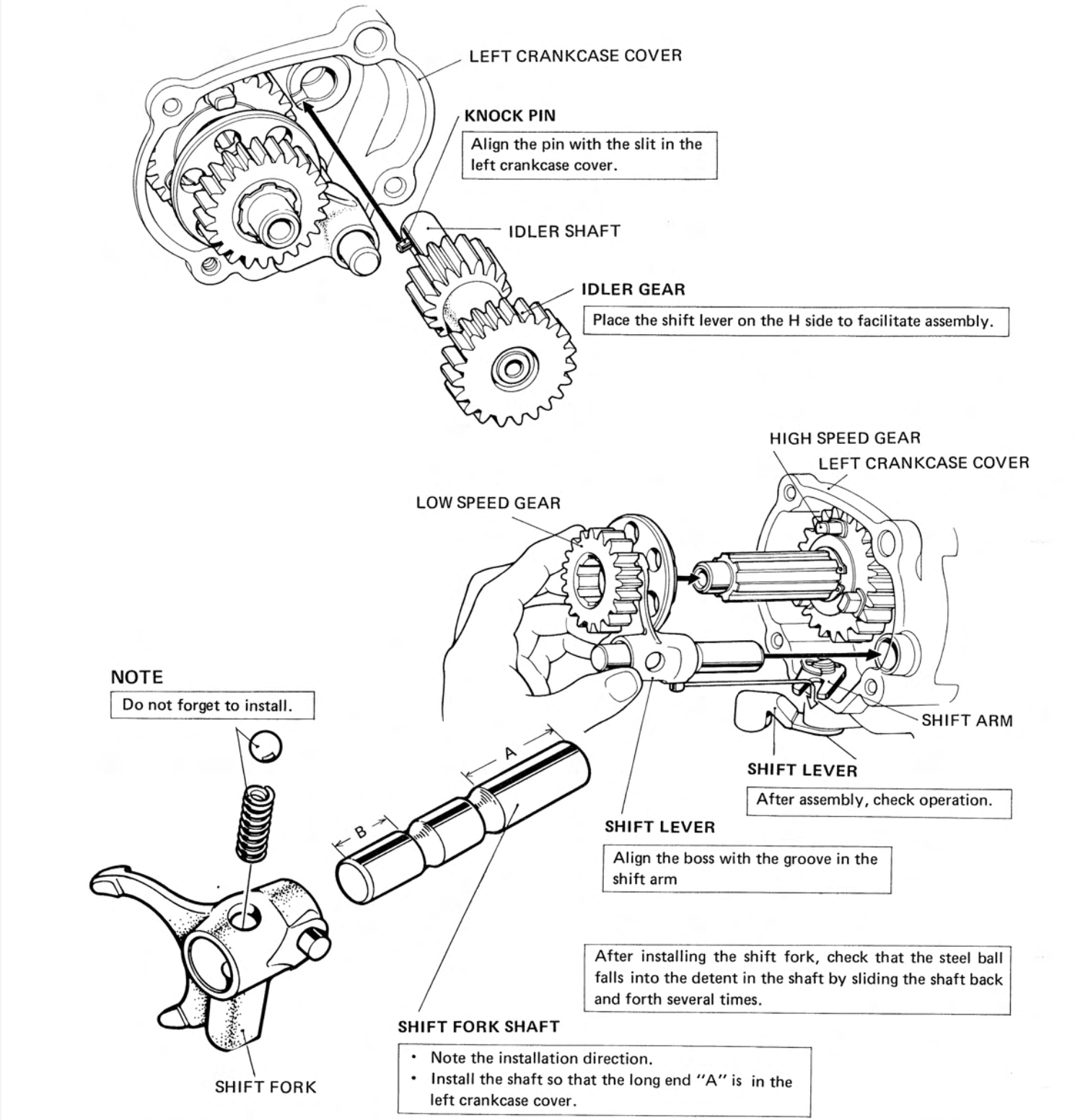

assembly

Note that if you need to remove the left crankcase cover you have to remove the sub transmission gears first (see below) since the high speed gear is held on to the counter shaft by a circlip:

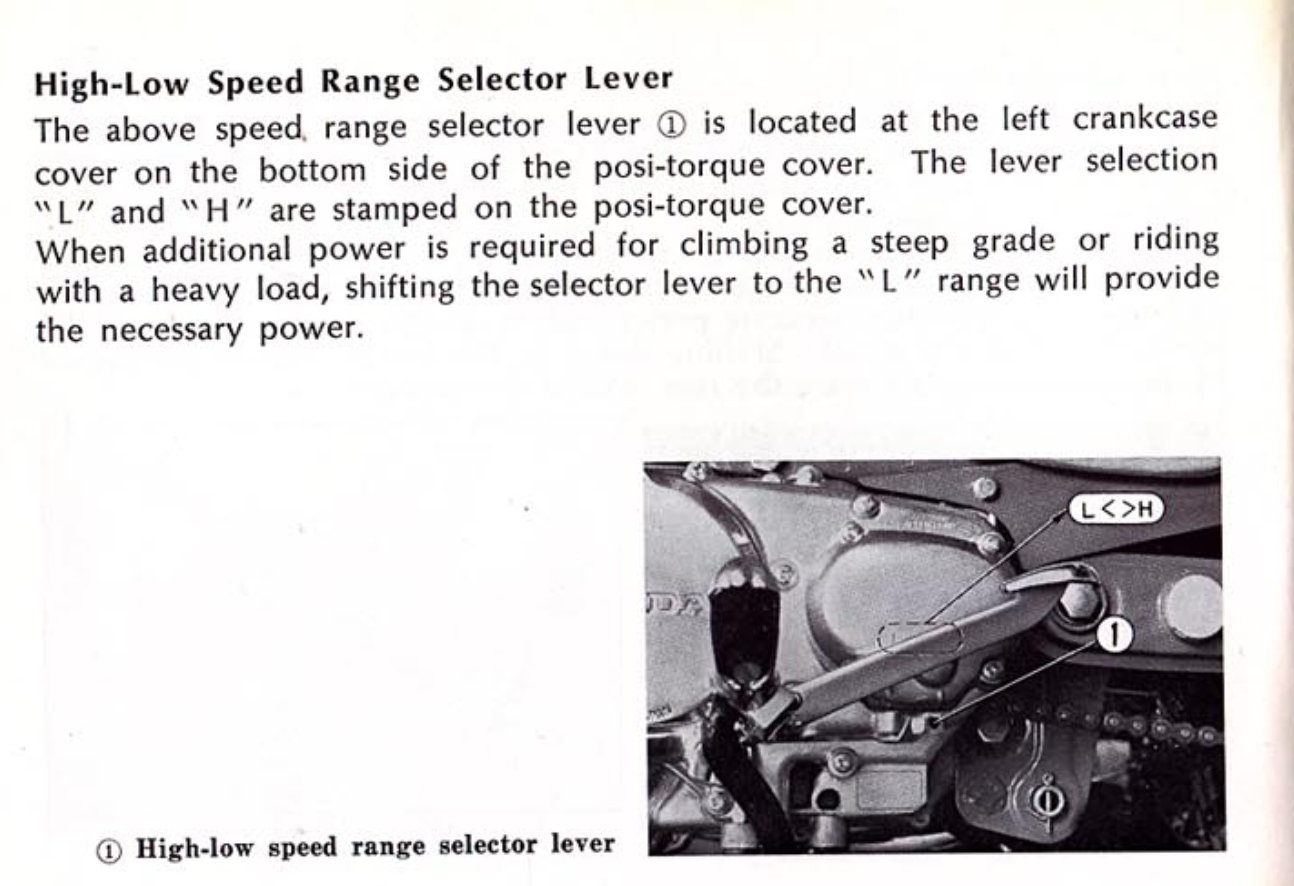

usage

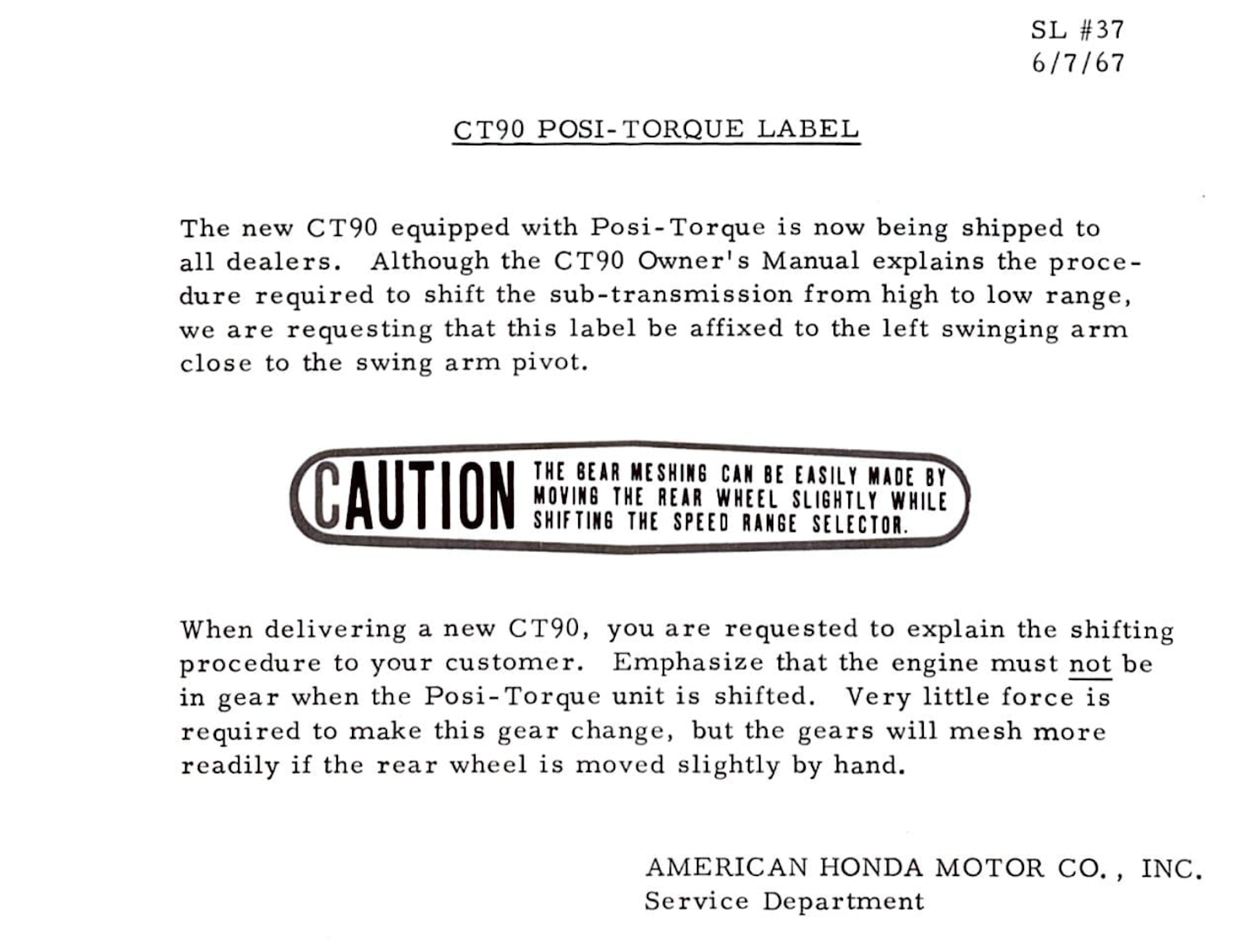

In theory selecting the low gear just requires a flick of the lever, however the action involves getting the low speed gear to mesh with the idler gear and in practice this means putting the bike into neutral and moving the back wheel until the gears align. The same technique is used to move from low to high, and moving the wheel helps the dog holes in the low speed gear align with the dogs on the low speed gear. When it is all set up correctly the lever will move with a positive clunk as the spring-loaded ball in the shift fork engages with one of the two detents in the shift fork shaft.

the original user manual (left) did not explain how to use the posi-torque mechanism / (right) a new sticker expanding on the instructions was issued later that year.

performance

If you want to know about the maths behind the graphs and tables below, you can read my article on the C90 engine performance. The ratios for the transmission when in the high range are as follows:

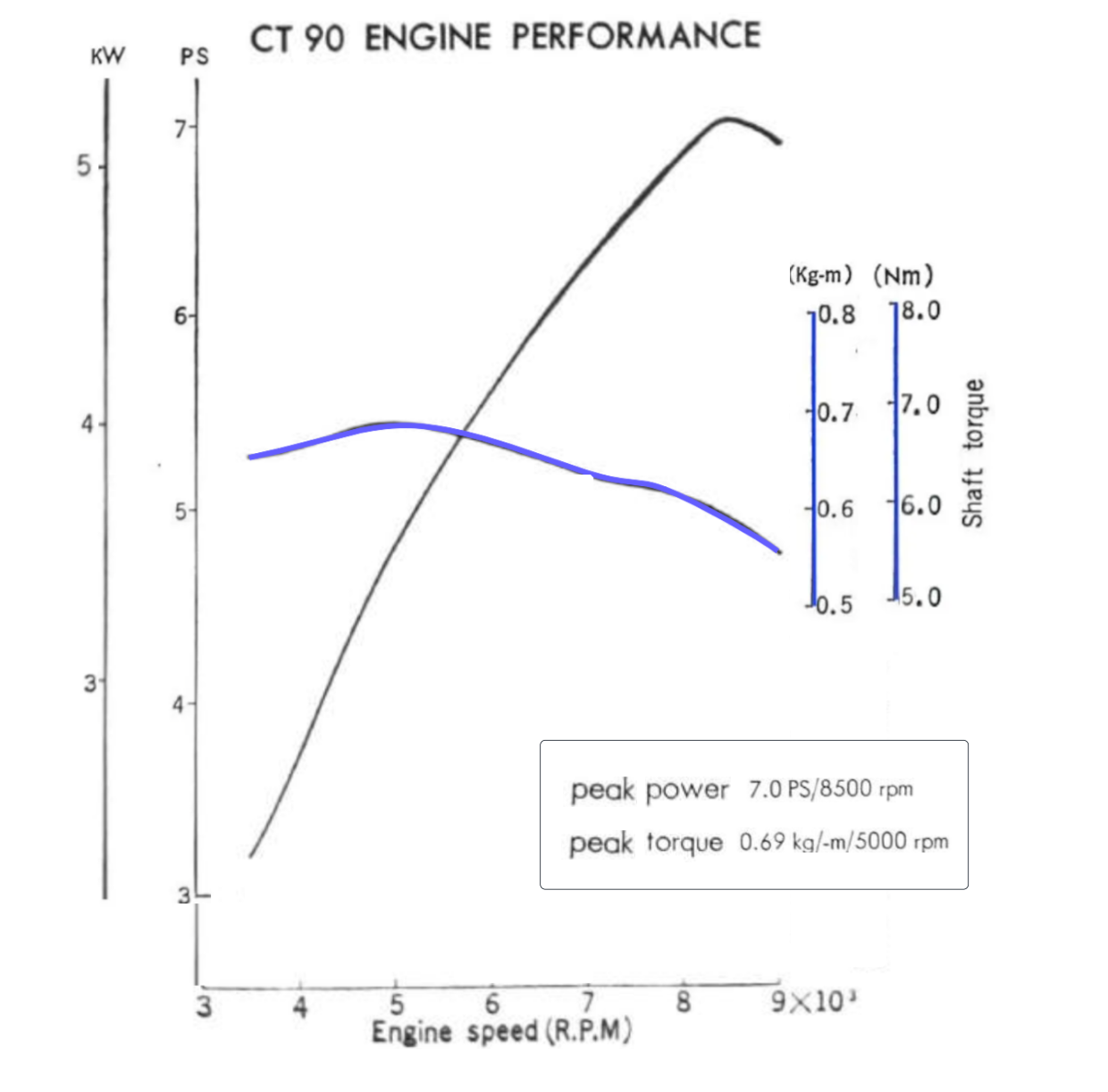

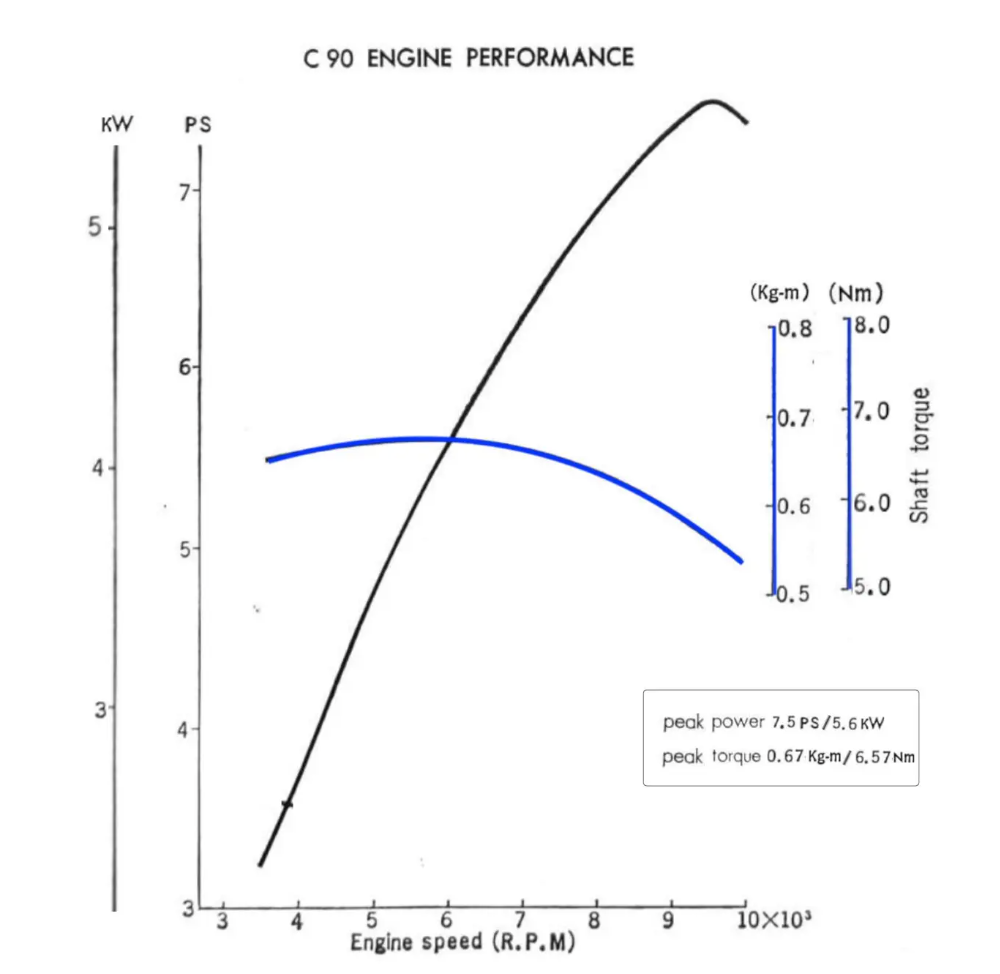

... the engine is slightly detuned compared to the C90 of the same era, making peak power of 7hp at 8500 compared to the 7.5hp/9500 C90. This seems to be the result of fitting a smaller carb and a more restrictive silencer:

Note that performance may have changed for bikes created after the charts below were produced (1969/1970) due to the various carburettor configurations fitted on later models, including changes made to accommodate increasingly rigorous emissions rules that applied in the USA during the 1970s.

ct90 performance (left) and C90 performance (right)

The engine will rev to about 9000rpm, translating to the following theoretical maximum top speeds in each gear:

When in low speed mode the 28 tooth high speed gear in the posi-torque sub-transmission is driven by the 15 tooth gear on the idler shaft, reducing the speed by 1.87. The theoretical top speeds in this mode are as follows:

This is equivalent to swapping out your 45 tooth rear drive sprocket for an 84 tooth/1ft diameter sprocket with the flick of a switch. A brilliant invention!

real world performance

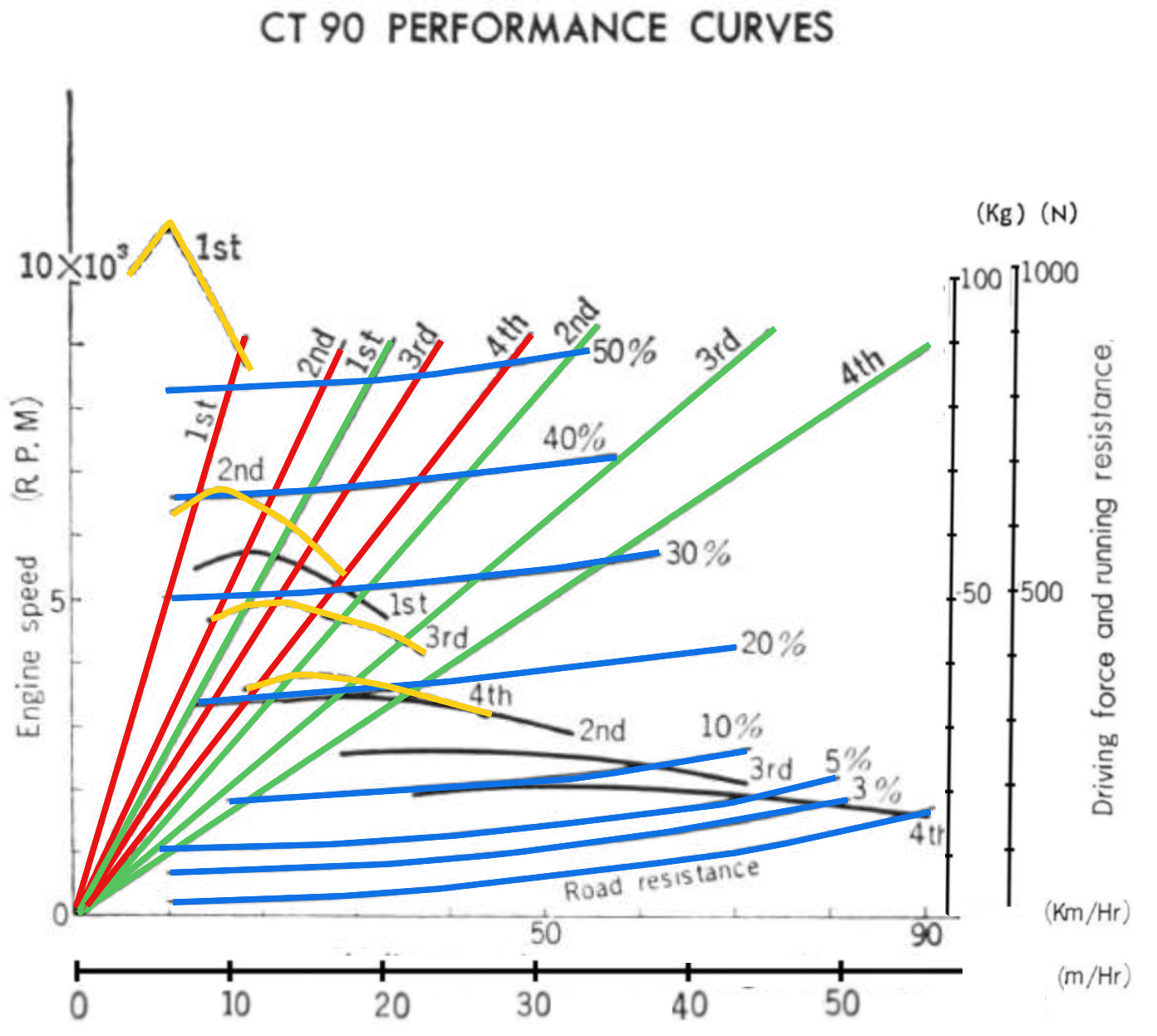

Honda includes a rather busy chart in the 1971 manual showing how these theoretical speeds translate into real world performance:

The green and red lines show the values in the tables above, namely the theoretical speeds that can be achieved if the bike did not encounter any of the opposing forces that prevent the bike from accelerating in real life (the red lines show the performance when using the low gears and the green lines are high gears).

The yellow and black lines show the driving force (torque at the rear wheel) at different engine speeds for the low gear range and high gear range respectively

Honda calls the forces that oppose forward motion (air resistance and friction between the wheels and the ground) running resistance or road resistance. These are shown by the blue lines, with the bottom blue line showing the resistance on a level road, and the lines above showing resistance for increasingly large gradients (more driving force is required when you go up a hill as the weight of the vehicle, in effect, must be lifted from the bottom to top).

Where the driving force and the running resistance lines cross on the chart, the forces will equal out and the bike can no longer accelerate. So according to this chart, the engine is capable of accelerating to 10mph when tackling a 40 degree incline in the 2nd low gear, improbable as that may be in practice (the spec sheet in the same manual has a more plausible entry under 'climbing ability': High range 18°/ Low range 25°)

Keep in mind that Honda tested their bikes in optimal conditions with a perfectly maintained bike and assumed the rider lying flat to minimise air resistance when calculating rolling resistance. Your mileage may vary!